Objective:

Lead the entire design and development (from scratch) of all exterior and interior lighting for the new Izera brand, establishing a unique visual signature while integrating innovative technology within strict cost, performance, and regulatory frameworks.

My Role & Responsibilities:

As the sole technical lead, I directed all engineering aspects - from concept feasibility with the design studio (using CATIA V5) to technical specifications, supplier strategy, and ensuring a clear path to homologation. My responsibilities included leading cross-functional teams, managing international suppliers, defining requirements (legal, performance, cost), creating technical specifications, cost estimations, project timelines, and championing innovative lighting designs to executive management.

Key Challenges & Solutions:

- Premium Look vs. Budget: Balanced high-tech features (e.g., Matrix LED) with cost-savvy components via extensive supplier negotiations, innovative component selection, and meticulous design trade-offs. Championed designs that maximized perceived value.

- Start-Up Ambiguity: Created clear engineering pathways and communication structures in a new OEM environment. Prepared detailed technical presentations for management and proactively mediated between design aspirations and technical/budgetary feasibility.

Outcomes & Achievements:

Successfully navigated project through Concept Freeze and Supplier Nomination milestones. Delivered Mockup Designs for key lighting components. Established foundational lighting system architecture and technical specifications for the Izera brand.

Tools & Technologies:

CATIA V5, Teamcenter, Jira, Excel, LED, Matrix/Pixel, OLED technologies, Agile & V-Model methodologies.

Industry Relevance:

Demonstrates ability to lead complex system development from zero, manage stringent requirements, and integrate novel technologies in a new venture - skills highly applicable to pioneering projects in advanced technology sectors.

Objective:

Design the entire roof structure and integrate all top-mounted electrical systems (including pantographs) for a completely new locomotive model (Dragon), ensuring structural integrity, weather resistance, and manufacturability while meeting demanding rail industry standards.

My Role & Responsibilities:

Responsible for the complete mechanical design of this critical section, from concept through detailed engineering using Autodesk Inventor. This included large-scale sheet metal and welded assemblies, heavy equipment integration, and direct production supervision. Managed documentation in Autodesk Vault and collaborated with electrical, simulation, and production teams.

Key Challenges & Solutions:

- Strength vs. Weight: Employed optimized structural design principles and material selection in Inventor, performing iterative analysis (in collaboration with simulation teams) to achieve a robust yet weight-efficient design.

- Large Assembly Tolerances/Sealing: Developed detailed GD&T schemes suitable for large fabrications and designed innovative sealing solutions, working closely with the production team to validate feasibility.

Outcomes & Achievements:

Successfully designed and implemented the roof structure for the highly successful Dragon locomotive model. Ensured full compliance with all structural, operational, and stringent railway regulatory requirements. Streamlined assembly through close production supervision.

Tools & Technologies:

Autodesk Inventor, Autodesk Vault, Excel, Sheet Metal Design, Advanced Welding Techniques, Rail Industry Standards.

Industry Relevance:

Demonstrates proficiency in designing large-scale structures for harsh, high-vibration environments, managing complex equipment integration, and ensuring reliability under demanding operational loads - directly analogous to challenges in designing vehicle, aircraft, or launch vehicle/ground support structures.

Objective:

Assume leadership of a complex R&D project mid-development, resolve existing technical issues, and successfully guide the Mercedes W177 rear lamp through development, validation, and homologation to achieve a timely 'green PPAP' and production launch, meeting premium OEM standards.

My Role & Responsibilities:

Led the multi-disciplinary R&D team (Mechanics, Optics, Electronics, etc.) and acted as the primary technical interface with Mercedes-Benz. Responsible for all technical decisions, deliverables, budget, and leading the team through critical problem-solving and validation phases. Drove intensive problem-solving efforts post-first-tooling.

Key Challenges & Solutions:

- Project Turnaround: Successfully identified and resolved numerous 'hidden' technical issues inherited mid-project by implementing rigorous root-cause analysis processes and driving decisive technical actions.

- Stringent OEM & Homologation: Met demanding, evolving requirements and achieved full homologation despite tooling and timeline pressures by proactively negotiating with the client and internal teams, and managing technical risks meticulously.

Outcomes & Achievements:

Achieved 'Green PPAP' status on schedule - full customer approval. Successfully launched the product into serial production for a high-volume vehicle. Met all demanding Mercedes-Benz quality & performance metrics.

Tools & Technologies:

Catia V5, Excel, Valeo Development Process, PPAP, Homologation Standards (ECE), Problem-Solving Methodologies, DFMEA, DFM.

Industry Relevance:

Highlights experience in managing R&D for safety-critical systems under extremely stringent quality and validation protocols, similar to those in automotive and aerospace. Demonstrates resilience and leadership in high-stakes troubleshooting.

Objective:

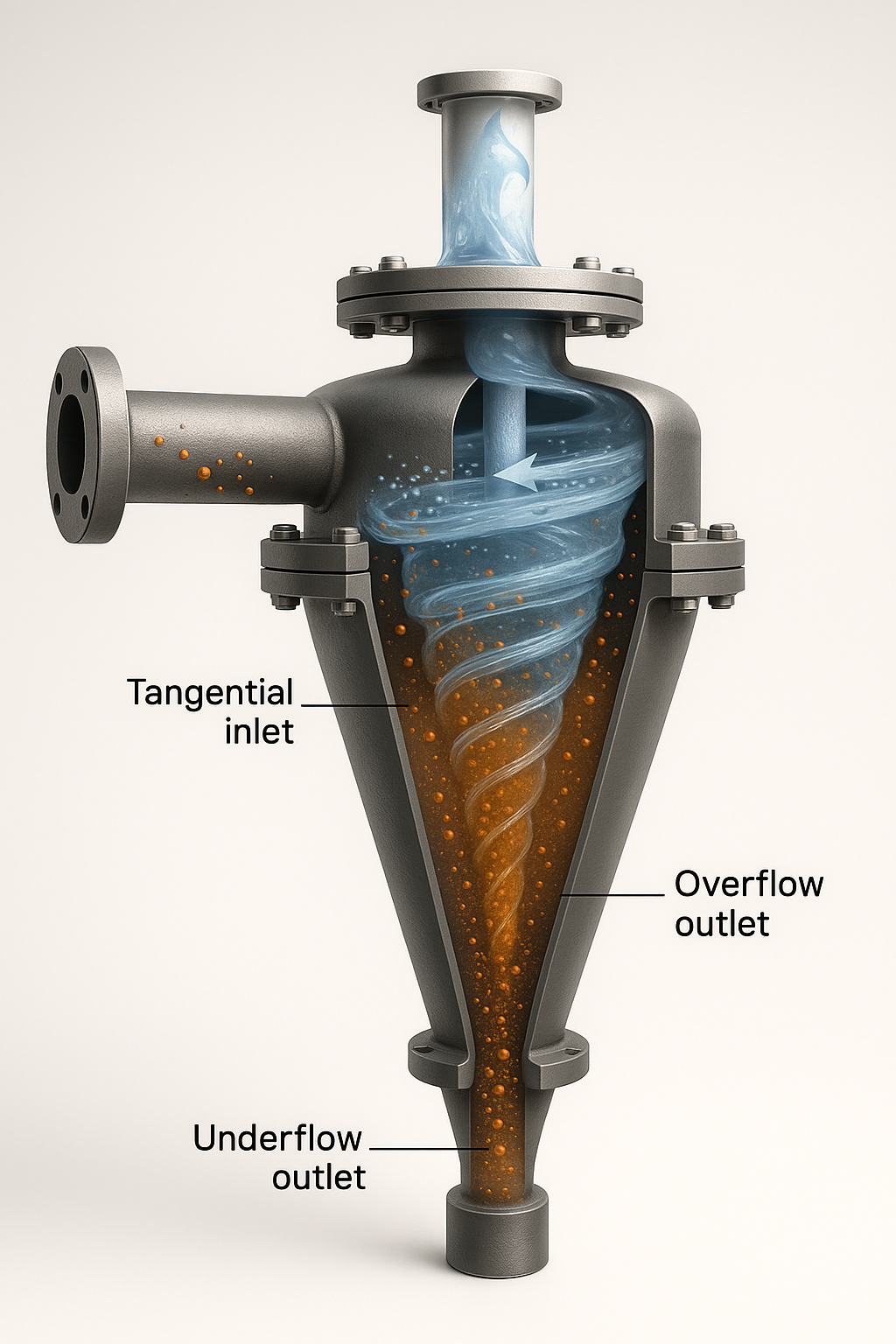

Design, develop, and adapt hydrocyclone systems using advanced plastic and composite materials for harsh sewage treatment environments in Polish power plants. Focus on high separation efficiency, long-term chemical/abrasion resistance, and successful client implementation.

My Role & Responsibilities:

Managed the end-to-end engineering process: conceptual and final design (part & mold) using Autodesk Inventor & Fusion 360, material selection, FEA/CEA validation (stress, flow, durability), production supervision, and direct client management including installation support and negotiations.

Key Challenges & Solutions:

- Harsh Environment Durability: Solved long-term chemical/abrasion issues via extensive material research, testing, and selecting high-performance composites. Utilized FEA/CEA to optimize designs against wear and chemical degradation.

- Complex Mold Design: Developed innovative mold designs for complex, hand-molded composite parts in close collaboration with production, leveraging Inventor/Fusion 360 for detailed modeling.

Outcomes & Achievements:

Successfully designed & installed systems in multiple Polish power plants. Met and exceeded client performance expectations, leading to repeat business. Gained deep expertise in composite design & FEA.

Tools & Technologies:

Autodesk Inventor, Fusion 360, AutoCAD, FEA/CEA Software, Advanced Composites & Plastics, Hand Molding & Casting.

Industry Relevance:

Directly demonstrates experience in designing components for extreme/harsh environments and utilizing advanced materials (composites) - both critical aspects of hardware design in demanding sectors. Shows strong FEA validation skills.

Objective:

Responsible for the design and development of the integrated headlamp fog function, working as part of the team on the Skoda Karoq & Kodiaq facelifts. Contributed through the full design cycle (RFQ to Tool Go) to deliver a production-ready, high-quality solution meeting performance, packaging, and cost targets, while navigating mid-project technology changes.

My Role & Responsibilities:

Owned the complete design from concept to final documentation. This involved hands-on CATIA V5 modeling, 2D drawing creation, Design for Manufacturing (DFM) for injection molded parts, and cross-functional coordination. Managed a critical technology change in the middle of development process.

Key Challenges & Solutions:

- Packaging & Thermal Constraints: Developed innovative designs to fit the function & manage heat within tight headlamp spaces via detailed CATIA V5 iterations and close work with optical/simulation engineers.

- Mid-Project Tech Change: Showcased agility by rapidly re-evaluating concepts, redesigning all affected components, and coordinating with stakeholders to implement the change efficiently, preventing Tool Go delays.

Outcomes & Achievements:

Successfully launched the design; now in production & on the road in Skoda Karoq & Kodiaq vehicles. Met all Skoda performance, cost, and quality targets. Delivered a robust, Tool Go approved design.

Tools & Technologies:

Catia V5, Teamcenter, Excel, Automotive Lighting (Bulb Technology), Automotive Lighting (LED Technology) Injection Molding Design, DFM.

Industry Relevance:

Highlights core skills in detailed mechanical design, DFM for complex assemblies, managing strict packaging constraints, and executing cost/performance trade-offs - vital for efficient & reliable hardware in advanced manufacturing.

Objective:

Design and coordinate the mechanical integration and retrofitting of ETCS Level 2 systems onto existing locomotive platforms for Alstom.

My Role & Responsibilities:

Responsible for mechanical design, creating documentation, ensuring fitment, and coordinating with electrical and installation teams to ensure seamless integration while adhering to strict rail safety and operational standards.

Outcomes & Achievements:

Successfully delivered mechanical design packages enabling ETCS L2 upgrades, enhancing locomotive safety and interoperability across European networks.

Tools & Technologies:

CAD Software (CATIA/Inventor), Rail Industry Standards, ETCS Specifications.